[av_submenu which_menu=’custom’ menu=’20’ position=’center’ sticky=’aviaTBsticky’ color=’main_color’ mobile=’disabled’ mobile_switch=’av-switch-768′ alb_description=” id=” custom_class=” av_uid=’av-kb15yqul’]

[av_submenu_item title=’Digi-Gage Plus’ button_style=” link=’page,3420′ linktarget=” av_uid=’av-g3t9to’]

[av_submenu_item title=’Vari-Gage Plus’ button_style=” link=’page,3424′ linktarget=” av_uid=’av-dl5ljg’]

[av_submenu_item title=’Electrogage ECO’ button_style=” link=’page,3428′ linktarget=” av_uid=’av-cyx23g’]

[av_submenu_item title=’Logic Chassis’ button_style=” link=’page,4117′ linktarget=” av_uid=’av-14s1v0′]

[av_submenu_item title=’BAMS’ button_style=” link=’page,4125′ linktarget=” av_uid=’av-9pl5ws’]

[av_submenu_item title=’SPV700EC’ button_style=” link=’page,4136′ linktarget=” av_uid=’av-7w1c7g’]

[av_submenu_item title=’Digi-Gage’ button_style=” link=’page,3418′ linktarget=” av_uid=’av-66kbzw’]

[av_submenu_item title=’Vari-Gage’ button_style=” link=’page,3422′ linktarget=” av_uid=’av-dswfw’]

[av_submenu_item title=’Electrogage’ button_style=” link=’page,3426′ linktarget=” av_uid=’av-266pss’]

[av_submenu_item title=’Slim View’ button_style=” link=’page,4582′ linktarget=”]

[/av_submenu]

[av_textblock size=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” font_color=” color=” id=” custom_class=” av_uid=’av-kay30893′ admin_preview_bg=”]

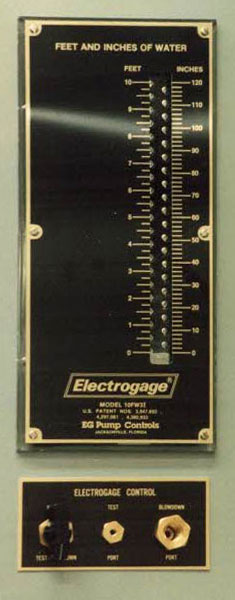

Electrogage™

Product Status: NOT ACTIVE

The Electrogage has been replaced by the Electrogage ECO

Liquid Level Indicator / Controller

Product Overview

The Electrogage is designed for use with purge bubbler systems but, can be usefully incorporated into any system where an electronically controlled and displayed liquid level is desired. As the liquid level increases above the bottom of the bubbler tube, the pressure increases in the purge system. The Electrogage senses this pressure and shows it clearly on it’s wide, easy to read indicating column.

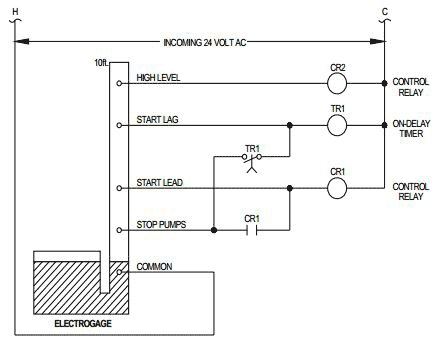

The Electrogage operates on a combination of two time proven principles. When pressure is applied to the well side of the manometer, it causes the mercury in the indicator column to rise accordingly to the amount of pressure applied. As the mercury rises and falls, it makes and breaks a series of contacts built into the indicating column. The number of contacts activated is proportional to the pressure applied and because of mercury’s electrical conductivity, it completes the contact circuits. These contacts are then used by the control circuitry to manage a vast array of pumps, valves, alarms and other components.

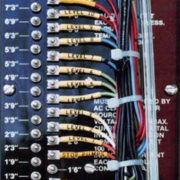

The Electrogage’s single common contact maintains an electrical connection with the mercury at all times. A series of 41 control contacts contained within the indicating column are precisely placed to exude an electrical output for every 3” of water pressure applied to the instrument.* Each contact is individually labeled to precisely indicate the level at which it will be activated. These control contacts may also be used to directly energize conventional electromechanical relays or PLC inputs, without any required interface devices, if so desired.

The Electrogage’s intuitive level control adjustments are simple and straightforward. Simply select the control contact for the level desired and wire to it. This enables the Electrogage to produce an electrical output at that precise liquid level without any adjustments or calibration needed.

The Electrogage is made of high quality, corrosion and impact resistant materials. Each is precision machined from a solid acrylic block with a guaranteed accuracy better than +/- ½ % of full scale and then carefully calibrated by the critical fill method and sealed with micro porous filters that pass air and gases but not mercury. Repeatable accuracy is 100% with zero dead bands when making and breaking electrical contacts.

Designed to be mounted on a vertical surface, the Electrogage can be remotely located up to 1000 feet from the liquid being measured without affecting accuracy. Rest assured in the Electrogage’s long term, repeatable precision as there is no moving parts that can lose calibration.

To ensure optimal function and condition of the Electrogage, recommended filter replacement is as follows:

- The two inline compressor filters (Part #FIL- 10A) should be replaced every 6-8 months. Filter discoloration may indicate that a replacement is needed.

- The charcoal filter (Part #FIL-2P) attached to the Electrogage should be replaced every 18-24 months.

Technical Specifications

- Dimensions: 12”H x 5.5” W x 1.5”D

- Control Circuit Wiring: 16 gauge minimum, type MTW or THW, rated for 300 volts.

- Air Compressor Recommendation: Minimum of .6 SCFH with a maximum air pressure of 5.5 PSIG (152 inches of water column)

- Accuracy: +/- ½% of full scale with 100% repeat accuracy

- Pressure Range: Maximum 15 psi

- Contact Rating: 5 VA, 24 VAC Maximum

- Range: 0 – 10’ water Consult factory for other ranges.

- Contains 0.47 lbs of 99.99% Pure Mercury

[/av_textblock]