[av_submenu which_menu=’custom’ menu=’20’ position=’center’ sticky=’aviaTBsticky’ color=’main_color’ mobile=’disabled’ mobile_switch=’av-switch-768′ alb_description=” id=” custom_class=” av_uid=’av-kb15yqul’]

[av_submenu_item title=’Digi-Gage Plus’ button_style=” link=’page,3420′ linktarget=” av_uid=’av-g3t9to’]

[av_submenu_item title=’Vari-Gage Plus’ button_style=” link=’page,3424′ linktarget=” av_uid=’av-dl5ljg’]

[av_submenu_item title=’Electrogage ECO’ button_style=” link=’page,3428′ linktarget=” av_uid=’av-cyx23g’]

[av_submenu_item title=’Logic Chassis’ button_style=” link=’page,4117′ linktarget=” av_uid=’av-14s1v0′]

[av_submenu_item title=’BAMS’ button_style=” link=’page,4125′ linktarget=” av_uid=’av-9pl5ws’]

[av_submenu_item title=’SPV700EC’ button_style=” link=’page,4136′ linktarget=” av_uid=’av-7w1c7g’]

[av_submenu_item title=’Digi-Gage’ button_style=” link=’page,3418′ linktarget=” av_uid=’av-66kbzw’]

[av_submenu_item title=’Vari-Gage’ button_style=” link=’page,3422′ linktarget=” av_uid=’av-dswfw’]

[av_submenu_item title=’Electrogage’ button_style=” link=’page,3426′ linktarget=” av_uid=’av-266pss’]

[av_submenu_item title=’Slim View’ button_style=” link=’page,4582′ linktarget=”]

[/av_submenu]

[av_textblock size=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” font_color=” color=” id=” custom_class=” av_uid=’av-kay1l9qm’ admin_preview_bg=”]

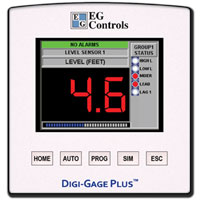

Digi-Gage Plus™

Product Status: ACTIVE

Digital Constant Speed Controller

The Digi-Gage Plus™ is a single compact SCADA ready system controller designed to automatically start, stop, alternate and precisely monitor & control fluid levels.

- Supports from 1 to 6 pumps from a single controller.

- Combines all current Digi-Gage models functions into one easy-to-use intuitive interface and single part number.

- Fits and functions within the existing Digi-Gage Classic footprint.

- Networkable, scalable, upgradable and expandable platform for integration into most SCADA packages.

Standard Features

Visual Indication

Pump mode (run/auto/fail), lead/lag sequencing, alternation, process level, high/low level alarms are displayed

Level Simulation

Level simulation to test setup function and alarm set points

Maximum Number of Pumps

Configure the maximum number of pumps to run at the same time.

Color Touch Screens

- Home Screen (Digi-Gage)

- Level & Pump Status Screen

- Configuration/Setup Screens

- Simulation Setup Screen

- Clean Out Feature Setup Screen

- Alarm History Screen

- Alarm Popup and Acknowledge Screen

- Reverse Pump function Setup Screen (Optional with addition of reversing contactors, pressure feedback and expanded input module)

Communications & Data

- TCP/IP Ethernet communications

- Local Level, Alarm Data Logging

- Remote Interface (Requires network connectivity)

- Phone App interface to monitor status (requires smart phone application)

- Web Server features

- Standard status and control address mapping for ease of SCADA integration

Status

- Pumps 1-6 Start Status, Auto & Fail

- Phase Loss, Float Backup, Intrusion Status

- Panel Alarm Status Output

Wet Well Clean Out (Flush) Mode

The system employs a user adjustable time/cycle set point to allow pumps to run beyond the normal level set points to flush wet well and help prevent buildup.

Wet Well FOG Buildup Reduction Mode

The system employs a changing level algorithm to help prevent grease buildup at a set level. This feature can be enabled/disabled by user.

Clog Prevention Mode

The system uses customer settable time or number of cycles to trigger a cycle that will oscillate the pump(s) reverse and forward to help prevent clogs or “rags” that may build up on the pump’s impeller.

Volume (Flow) Calculation

The system employs calculations based on pump characteristics and change of level to provide an estimated flow rate and display.

Advanced Alternation

The controller can alternate up to 6 pumps/blowers in the automatic operation mode and include the capability of selecting any pump/blower for the lead position(s) with or without alternation.

Advance Grouping

The system allows user to group any number of the 6 pumps/blowers into alternation groups. (Example: a 5 pump system can be operated as a duplex and triplex within the same controller).

Technical Data

Inputs/Outputs

Pump mode (run/auto/fail), lead/lag sequencing, alternation, process level, high/low level alarms are displayed

Level Simulation

Level simulation to test setup function and alarm set points

Maximum Number of Pumps

Configure the maximum number of pumps to run at the same time.

Color Touch Status

Panel Alarm Status Output

Hardware Ratings

- Operating Temperature: 0 to +60°C (32 to 140°F)

- Storage Temperature: -20 to +60°C (-4 to 140°F)

- Relative humidity: (RH) 10% to 95% (non-condensing)

- NEMA/IP Rating: NEMA4X/IP65/66

- Voltage range: 10.2 to 28.8VDC <10% ripple

-

- Power consumption: npn inputs 280mA @ 24VDC

- pnp inputs 190mA @ 24VDC

- Backlight 20mA @ 24VDC

- Ethernet card 35mA @ 24VDC

- Relay Outputs (ea.) 8mA @ 24VDC

-

System Ratings

- Input / Output Capacity is capable of supporting up to 256 I/O points (8 I/O modules maximum)

- Scan Rate of 15µs per 1kb ladder logic

- Adjustable white LED backlight TFT LCD display

- Up to 1024 displays

- Colors 65,536 (16-bit)

- 3.5” viewing area resistive, analog touchscreen

- 5 pre-programed function keys, sealed membrane

Other Features

- Remote access

- Micro SD Card backup/ upload/ logging

- Data logging

- OPC Server compliant

- DDE format read/ write

System Processor

- Memory: 1MB Application, 512k Fonts, 3MB Images.

- Removable memory: Standard SD or SDHC (32GB max)

- Real Time Clock

- Battery backup (7 years typical at 25°C), Replaceable, coin type, Lithium battery (CR2450)

Base Features

- Input voltage 24VDC

- 12 Digital inputs rated 24VDC (2 configurable as analog current/ voltage)

- 6 Relay outputs rated 5 amp at 250VAC/ 30VDC

- Comm Port 1: RS232/ RS485 (up to 32 nodes)

- Comm Port 2:Ethernet

Communication Interfaces (optional)

- Comm Port 1

-

- RS232/485 baud rates between 300 to 115200 bps

- RS485 up to 32 nodes/ 1200m (4000’) maximum

- USB 2.0 compliant; full speed

-

- Comm Port 2 (Optional)

-

- Ethernet

- RS232/485

- CANbus

-

[/av_textblock]