[av_one_full first min_height=” vertical_alignment=” space=” row_boxshadow=” row_boxshadow_color=” row_boxshadow_width=’10’ custom_margin=” margin=’0px’ mobile_breaking=” border=” border_color=” radius=’0px’ padding=’0px’ column_boxshadow=” column_boxshadow_color=” column_boxshadow_width=’10’ background=’bg_color’ background_color=” background_gradient_color1=” background_gradient_color2=” background_gradient_direction=’vertical’ src=” background_position=’top left’ background_repeat=’no-repeat’ highlight=” highlight_size=” animation=” link=” linktarget=” link_hover=” title_attr=” alt_attr=” mobile_display=” id=” custom_class=” aria_label=” av_uid=’av-8fsb5c’]

[av_timeline orientation=’vertical’ placement_v=’alternate’ placement_h=’top’ slides_num=’3′ content_appearence=” custom_date_size=” av-medium-font-size-title=” av-small-font-size-title=” av-mini-font-size-title=” custom_title_size=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” custom_content_size=” contentbox_bg_color=” custom_contentbox_bg_color=” font_color=” custom_date=” custom_title=” custom_content=” icon_color=” icon_custom_bg=” icon_custom_font=” icon_custom_border=” animation=” alb_description=” id=” custom_class=” av_uid=’av-q160g’ admin_preview_bg=”]

[av_timeline_item date=’1969′ title=’First control panel built’ icon_image=’icon’ number_arrow=” icon=’ue808′ font=’entypo-fontello’ image=’http://www.egcontrols.com/wp-content/themes/enfold/config-templatebuilder/avia-template-builder/images/placeholder.jpg’ attachment=” attachment_size=” milestone_valign=’baseline’ milestone_color=” custom_milestone_color=” link=” linktarget=” linkelement=’all’ custom_id=” custom_class=” av_uid=’av-62a18w’]

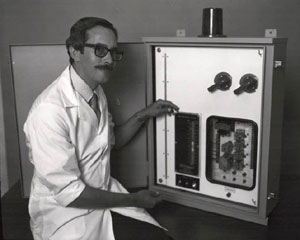

Electromate Engineer Carl Hoyt has a team of part time new hires build a working panel on a two wheel hand truck as a sales demonstrator. This first panel was a duplex lift station panel in an aluminum enclosure. Company founder, Andy Irvin pictured with panel.

Electromate Engineer Carl Hoyt has a team of part time new hires build a working panel on a two wheel hand truck as a sales demonstrator. This first panel was a duplex lift station panel in an aluminum enclosure. Company founder, Andy Irvin pictured with panel.

[/av_timeline_item]

[av_timeline_item date=’Early 1970’s’ title=’OEM Repeat Panels’ icon_image=’icon’ number_arrow=” icon=’ue863′ font=’entypo-fontello’ image=’http://www.egcontrols.com/wp-content/themes/enfold/config-templatebuilder/avia-template-builder/images/placeholder.jpg’ attachment=” attachment_size=” milestone_valign=’baseline’ milestone_color=” custom_milestone_color=” link=” linktarget=” linkelement=’all’ custom_id=” custom_class=” av_uid=’av-k36wj4′]

Electromate has 2 great contracts producing cardboard compactor and cardboard baler panels.

[/av_timeline_item]

[av_timeline_item date=’1976′ title=’Flagship product: Electrogage’ icon_image=’icon’ number_arrow=” icon=’ue82a’ font=’entypo-fontello’ image=’http://www.egcontrols.com/wp-content/themes/enfold/config-templatebuilder/avia-template-builder/images/placeholder.jpg’ attachment=” attachment_size=” milestone_valign=’baseline’ milestone_color=” custom_milestone_color=” link=” linktarget=” linkelement=’all’ custom_id=” custom_class=” av_uid=’av-4xxpao’]

During this time, pressure switch industrial control panels were massive. Andy’s Electrogage invention that used a specially designed, extremely precise, and calibrated manometer which allowed lift station control panels to be manufactured significantly smaller and more accurate.

[/av_timeline_item]

[av_timeline_item date=’1976′ title=’Logic Chassis’ icon_image=’icon’ number_arrow=” icon=’ue82a’ font=’entypo-fontello’ image=’http://www.egcontrols.com/wp-content/themes/enfold/config-templatebuilder/avia-template-builder/images/placeholder.jpg’ attachment=” attachment_size=” milestone_valign=’baseline’ milestone_color=” custom_milestone_color=” link=” linktarget=” linkelement=’all’ custom_id=” custom_class=” av_uid=’av-1tz4zk’]

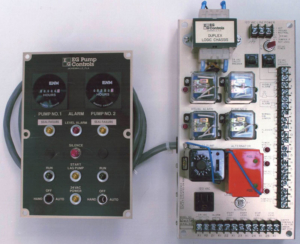

The Electrogage was never a UL508A product. It was controlled with 24VAC from the Logic Chassis which is allowed by UL because of the safe level of voltage. The Logic Chassis was also a customer focused product. The components were laid out in a easy to follow fashion and all parts were labeled making a non electrical person able to trouble shoot a panel with phone support.

[/av_timeline_item]

[av_timeline_item date=’1978′ title=’Air Transfer Chassis (ATC 10)’ icon_image=’icon’ number_arrow=” icon=’ue82a’ font=’entypo-fontello’ image=’http://www.egcontrols.com/wp-content/themes/enfold/config-templatebuilder/avia-template-builder/images/placeholder.jpg’ attachment=” attachment_size=” milestone_valign=’baseline’ milestone_color=” custom_milestone_color=” link=” linktarget=” linkelement=’all’ custom_id=” custom_class=” av_uid=’av-g3bi74′]

The ATC 10 was created as an extention of the Logic Chassis using pneumatic control.

[/av_timeline_item]

[av_timeline_item date=’1980′ title=’Bubbler Air Monitoring System (BAMS)’ icon_image=’icon’ number_arrow=” icon=’ue82a’ font=’entypo-fontello’ image=’http://www.egcontrols.com/wp-content/themes/enfold/config-templatebuilder/avia-template-builder/images/placeholder.jpg’ attachment=” attachment_size=” milestone_valign=’baseline’ milestone_color=” custom_milestone_color=” link=” linktarget=” linkelement=’all’ custom_id=” custom_class=” av_uid=’av-5n1c5s’]

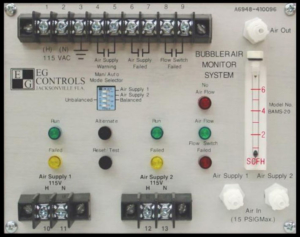

The BAMS was the successor to the ATC 10 as part of the Logic Chassis. The BAMS alternated the small enclosure air compressors and would alert an operator if one or both compressors failed.

[/av_timeline_item]

[av_timeline_item date=’Mid 1980s’ title=’Electromate starts building panels with frequency drives (VFDs)’ icon_image=’icon’ number_arrow=” icon=’ue863′ font=’entypo-fontello’ image=’http://www.egcontrols.com/wp-content/themes/enfold/config-templatebuilder/avia-template-builder/images/placeholder.jpg’ attachment=” attachment_size=” milestone_valign=’baseline’ milestone_color=” custom_milestone_color=” link=” linktarget=” linkelement=’all’ custom_id=” custom_class=” av_uid=’av-c1lnw0′]

Back in the 1980’s VFDs were like computers of the era. Very expensive, very large and very few people understood or were qualified to work on them. When a VFD broke, it meant putting a highly trained factory engineer on a plane for emergency service. Electromate required VFD panels to have contactor bypass. If a VFD failed in the field, a flip of a switch kept the control panel in service and the VFD could be serviced minus the emergency costs. Other measures were also taken by Electromate to keep panels going including float back up for transducers and redundant PLCs.

[/av_timeline_item]

[av_timeline_item date=’1983′ title=’Zap Trap’ icon_image=’icon’ number_arrow=” icon=’ue82a’ font=’entypo-fontello’ image=’http://www.egcontrols.com/wp-content/themes/enfold/config-templatebuilder/avia-template-builder/images/placeholder.jpg’ attachment=” attachment_size=” milestone_valign=’baseline’ milestone_color=” custom_milestone_color=” link=” linktarget=” linkelement=’all’ custom_id=” custom_class=” av_uid=’av-b8r7mo’]

Since electrical equipment and especially VFDs are sensitive to lighting, Electromate designed and made their own surge arrestors.

Since electrical equipment and especially VFDs are sensitive to lighting, Electromate designed and made their own surge arrestors.

[/av_timeline_item]

[av_timeline_item date=’1984′ title=’Pump Station Director’ icon_image=’icon’ number_arrow=” icon=’ue82a’ font=’entypo-fontello’ image=’http://www.egcontrols.com/wp-content/themes/enfold/config-templatebuilder/avia-template-builder/images/placeholder.jpg’ attachment=” attachment_size=” milestone_valign=’baseline’ milestone_color=” custom_milestone_color=” link=” linktarget=” linkelement=’all’ custom_id=” custom_class=” av_uid=’av-35bqq8′]

Running variable frequency drives (VFDs), and some of the most sophisticated programmable logic controllers (PLCs) available at the time, Electromate made monochrome touchscreen control panels. The Pump Station Director panels were ahead of their time. The panels measured and displayed information to extreme detail and measured every conceivable variable. The engineers and programmers working for Electromate wrote a software called “Shazam” designed to determine the most economical conditions for the panel to run. Shazam prolonged equipment life and saved site owner capital with attenuated energy costs.

Because of the large sticker price, not many Pump Station Directors were manufactured. Many of these panels are still in service and have paid their investment back in spades with energy savings. Keep in mind, this was in the 1980s, a lot of these things were not on peoples’ minds for a few more decades.

[/av_timeline_item]

[av_timeline_item date=’1986′ title=’Pump Station Director Junior’ icon_image=’icon’ number_arrow=” icon=’ue82a’ font=’entypo-fontello’ image=’http://www.egcontrols.com/wp-content/themes/enfold/config-templatebuilder/avia-template-builder/images/placeholder.jpg’ attachment=” attachment_size=” milestone_valign=’baseline’ milestone_color=” custom_milestone_color=” link=” linktarget=” linkelement=’all’ custom_id=” custom_class=” av_uid=’av-78aleo’]

As a way of increasing the target market for the Pump Station Director, the PSD JR. was designed with more “necessary only” features and functionality. Unfortunately industrial control panels like these would not be interesting to most municipalities or site owners for a while yet. Pump Station Director Junior panels are very similar to PLC controlled, VFD driven duplex and triplex panels manufactured by panel shops today.

The PSD JR did not get the popularity needed to continue on as a sellable product. Electromate had a great idea but was approximately 2 decades early to the party.

[/av_timeline_item]

[av_timeline_item date=’1988′ title=’Lift Station Controller & Booster Station Controller’ icon_image=’icon’ number_arrow=” icon=’ue82a’ font=’entypo-fontello’ image=’http://www.egcontrols.com/wp-content/themes/enfold/config-templatebuilder/avia-template-builder/images/placeholder.jpg’ attachment=” attachment_size=” milestone_valign=’baseline’ milestone_color=” custom_milestone_color=” link=” linktarget=” linkelement=’all’ custom_id=” custom_class=” av_uid=’av-65krxs’]

Another attempt was made to bring sophisticated automation and energy savings to water / waste water. The LSC and BSC were designed around customer feedback with the PSDs. Both systems still had a high cost entry barrier and were way more control panel than needed at the time.

[/av_timeline_item]

[av_timeline_item date=’1989′ title=’The Game Changers: Digi-Gage and Vari-Gage’ icon_image=’icon’ number_arrow=” icon=’ue82a’ font=’entypo-fontello’ image=’http://www.egcontrols.com/wp-content/themes/enfold/config-templatebuilder/avia-template-builder/images/placeholder.jpg’ attachment=” attachment_size=” milestone_valign=’baseline’ milestone_color=” custom_milestone_color=” link=” linktarget=” linkelement=’all’ custom_id=” custom_class=” av_uid=’av-4s3va8′]

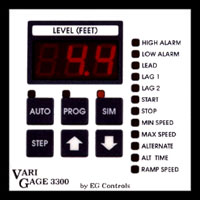

Electromate aquired a hardware division of a company that wanted to become a software-only company. The MicroMAC controlled across the line starters or variable frequency drives. The MicroMACs were retooled and sold as the Digi-Gage and Vari-Gage. The Digi-Gage came in 3 versions: 2300 – up to 3 pumps, 2400 – up to 4 pumps and 2600 – up to 6 pumps. The Vari-Gage controlled up to 3 pumps with variable frequency drives.

With well over 10,000 active installations, the Digi-Gage and Vari-Gage nailed the water / wastewater market. The systems were so simple to use but delivered the exact reliability and control a municipality or site owner needed. In the event either the Digi-Gage or Vari-Gage failed, a replacement could be user configured and hot swapped in minutes.

[/av_timeline_item]

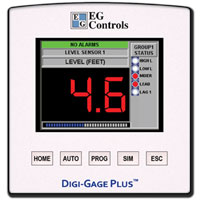

[av_timeline_item date=’2017′ title=’Electrogage ECO, Digi-Gage Plus & Vari-Gage Plus’ icon_image=’icon’ number_arrow=” icon=’ue82a’ font=’entypo-fontello’ image=’http://www.egcontrols.com/wp-content/themes/enfold/config-templatebuilder/avia-template-builder/images/placeholder.jpg’ attachment=” attachment_size=” milestone_valign=’baseline’ milestone_color=” custom_milestone_color=” link=” linktarget=” linkelement=’all’ custom_id=” custom_class=”]

The Electrogage used mercury for part of is functionality. The Electrogage had a significant amount of years invested in research and development to get around the use of mercury. The Electrogage ECO was created.

The Digi-Gage Plus and Vari-Gage Plus are the successors to the much loved Digi-Gage and Vari-Gage. Now as full color LCD touchscreens, The DG+ and VG+ can be controlled with a smartphone.

[/av_timeline_item]

[/av_timeline]

[/av_one_full]